Choosing the right enclosure influences safety, accessibility, and long-term reliability in commercial and industrial wiring. In many retrofit and new-build projects the Electrical Socket Box appears as a central component in the middle of cable routing plans and must be specified with attention to mounting, sealing, and thermal constraints. Early decisions about location, ingress protection, and termination methods around the Electrical Socket Box often determine whether a system is easy to service or becomes a persistent maintenance burden.

Core functions and typical applications

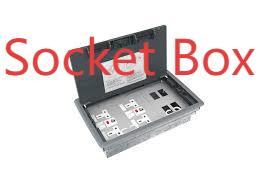

An electrical socket box serves multiple roles beyond simply holding a receptacle. It provides mechanical support for terminations, secures strain relief for incoming conductors, and can isolate live parts from accidental contact. In light industrial settings these boxes are used to feed machinery endpoints; in commercial buildings they form junctions for lighting, HVAC control, and AV systems. Understanding the intended application — fixed equipment, portable load, or frequent plug cycles — guides choices about box depth, mounting options, and whether to include additional features such as locking covers or integrated gland plates.

Materials, finishes, and environmental protection

Material selection affects service life and maintenance needs. Die-cast aluminum and stainless steel offer durability and impact resistance for harsh environments, while polycarbonate and fiberglass-reinforced polyester provide corrosion resistance and electrical isolation in damp or chemical-exposed zones. Pay attention to finish systems: powder coatings with proper surface preparation extend life outdoors, and UV-stabilized polymers resist embrittlement. When moisture or dust is a concern, choose enclosures and gaskets rated to the appropriate IP or NEMA level and ensure that all cable entries use compatible glands or conduit fittings to maintain the seal.

Mounting, wiring methods, and ergonomics

The way a socket box is mounted affects both installation speed and long-term serviceability. Flush-mounted boxes keep profiles neat but may be difficult to access during maintenance, while surface-mounted boxes simplify routing and future modifications. Consider the available clearances behind the box for conductor bending radii and the space needed to terminate lugs or screw connectors. Ergonomic considerations such as door swings, captive fasteners, and labeled compartment layouts reduce technician time and the chance of wiring mistakes. For high-use points, design with removable sub-panels so maintenance operations do not disturb adjacent circuits.

Nante product considerations and accessory options

When evaluating suppliers, look for documented accessory support: spare gaskets, gland kits, internal mounting panels, and locking hardware simplify field repairs and reduce downtime. A vendor that offers modular internal plates and standardized mounting footprints enables future upgrades without replacing the entire enclosure. Technical documentation — including torque specifications, recommended conductor sizes, and environmental test results — is essential for consistent installations across multiple sites. Where aesthetics matter, some suppliers provide color-matched covers or tamper-resistant finishes that blend with interior design while still meeting performance requirements.

Installation best practices and commissioning checks

Installation discipline prevents many common failures. Use the manufacturer’s recommended strip lengths and torque settings for lugs and terminal screws to avoid high-resistance joints. Seal all unused knockouts with rated plugs and apply thread sealant on conduit joints where needed to preserve ingress protection. During commissioning, perform insulation resistance checks and verify continuity of protective earth connections. A load test or thermal scan under normal operating conditions will identify abnormally warm terminations or undersized conductors before the system goes into full service.

Maintenance, inspections, and lifecycle planning

Routine inspection extends the useful life of socket box assemblies. Schedule visual checks for seal compression, corrosion, and signs of overheating such as discoloration or melting. Replace gaskets at the first sign of compression set, and keep commonly used spare parts on-site: replacement gaskets, mounting screws, and terminal kits reduce repair time. For high-cycle or high-current circuits, periodic thermal imaging helps detect developing hot spots. Capturing inspection data in a simple log aids trend analysis and informs future specification changes to mitigate recurring issues.

Design tips for specialized environments

Specific industries impose additional constraints. Food processing and pharmaceutical plants require smooth, cleanable surfaces and materials that withstand sanitizers. Marine and coastal installations need enhanced corrosion protection and sacrificial anodes or marine-grade alloys. In vibration-prone environments, prefer mechanical retention systems for components and screw-locking devices to preserve clamp torque. Customizable boxes with removable gland plates and internal baffling permit easy adaptation to unique site challenges without sacrificing protection.

Specifying the correct electrical socket box involves more than choosing a shape; it requires matching mechanical, electrical, and environmental needs with a sensible maintenance plan and vendor support. When teams focus on serviceability, clear documentation, and spare-part availability, installations remain reliable and manageable throughout their lifecycle. For further technical guidance, case studies, and product specifications, visit https://www.nante.com/news/industry-news/what-is-a-socket-box.html