On busy fabrication floors where safety and schedule pressures collide, welders and supervisors are paying closer attention to how consumables arrive and perform, and Aluminum Mig Wire Manufacturers often play an outsized role in that conversation. Choosing a supplier who supplies well wound spools, clear handling notes and consistent packaging reduces a surprising number of hazards and helps teams keep projects on track as renewable energy installations scale.

Start with personal protection and environment. Aluminum MIG welding generates bright ultraviolet radiation and spatter that can injure skin and eyes. Use an appropriate shade helmet face protection and flame resistant clothing that covers all exposed skin. Make ventilation a first order control. Even small indoor cells can trap fumes so ensure extract at source or use mobile ventilators to move contaminants away from breathing zones. In remote solar or wind sites where temporary shelters are common prioritize portable extraction and fresh air breaks for crews.

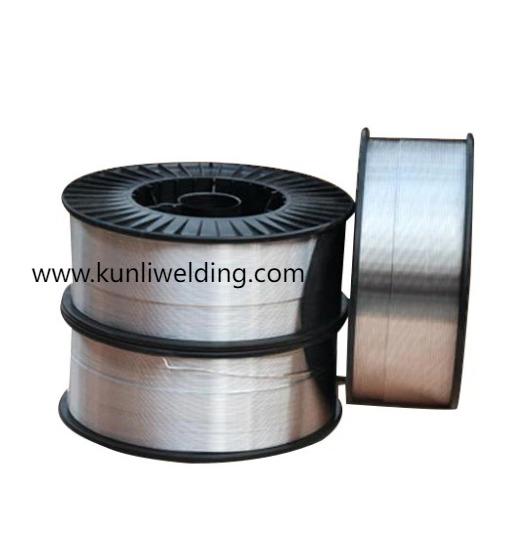

Feedability links directly to safety outcomes. Tangled or poorly wound wire can pull, kink or bird nest and cause erratic feed that surprises operators. When a feed fault happens at height or on an elevated scaffold it creates a fall risk as a technician scrambles to restore the feed. Buying from a supplier that emphasizes even winding protected flanges and recommendations for drive roll profiles reduces those surprises and keeps welders focused on the joint rather than on the feeder.

Control of moisture and surface films matters for weld integrity and for safety inspections. Aluminum wire that sits in humid storage can pick up films that increase porosity risk and create hidden defects that later require invasive repairs. Use sealed reels for storage and follow a simple acclimation routine once reels arrive on site so condensation does not form during handling. That practice lowers the chance of destructive rework and keeps inspection crews from uncovering hidden issues that force shutdowns.

Tool choice and setup affect operator control. Spool guns and push push systems each bring trade offs. For long seams a consistent feed path and compatible liner reduce reach problems and allow welders to maintain a safe posture. Confirm that cable routing and torch weight do not force awkward positions that fatigue the operator. Ergonomics reduce fatigue driven errors which account for a large share of on the job incidents.

Grounding and electrical safety are non negotiable. Aluminum MIG work often occurs near conductive assemblies and in wet or coastal environments. Confirm that workpieces are isolated where possible that clamps are secure and that temporary grounding straps are inspected daily. Use insulated platforms and ensure that power sources have reliable grounding and circuit protection appropriate for welding tasks.

Training and checklists bring consistency between shifts. A short arrival checklist covering spool inspection liner condition and quick run off helps technicians start welds from a known stable baseline. When suppliers supply concise handling notes and suggested drive roll settings a shop can standardize the checklist and reduce variation between operators and shifts. That consistency also speeds investigations when an unusual weld appears during inspection.

Field repairs present their own set of constraints. In renewable energy projects crews often work at height on panels or on towers where space is limited and weather is variable. Compact spool options sealed reels and clear warm up and cooling guidance let technicians maintain acceptable bead shape without repeated returns to base. Supplier kits that bundle small reels consumables and a short setup checklist make mobile repairs faster and reduce time at risky heights.

Inspection friendly practices lower rework risk and protect safety. Record the spool lot that produced a critical seam retain a short sample length and log the drive and travel settings. Those simple traceability steps let quality teams narrow an investigation quickly to a single lot rather than isolating entire fleets of assemblies. Fewer large scale holds mean fewer rushed repairs and lower pressure on teams to cut corners.

Finally, the growth of renewables increases demand and places a premium on consistent supply. When procurement and operations plan around suppliers that publish clear handling guidance and that offer trial reels, qualification moves faster and crews spend less time tuning and more time welding. That alignment between supplier packaging practice and field realities reduces both defect rates and safety exposures tied to rework and extended site time. For details on spool presentation packaging options and product notes for aluminum MIG wire suited to both shop floors and field repairs visit this product page: https://www.kunliwelding.com/product/aluminum-welding-wire/er5183-aluminum-welding-wire.html .