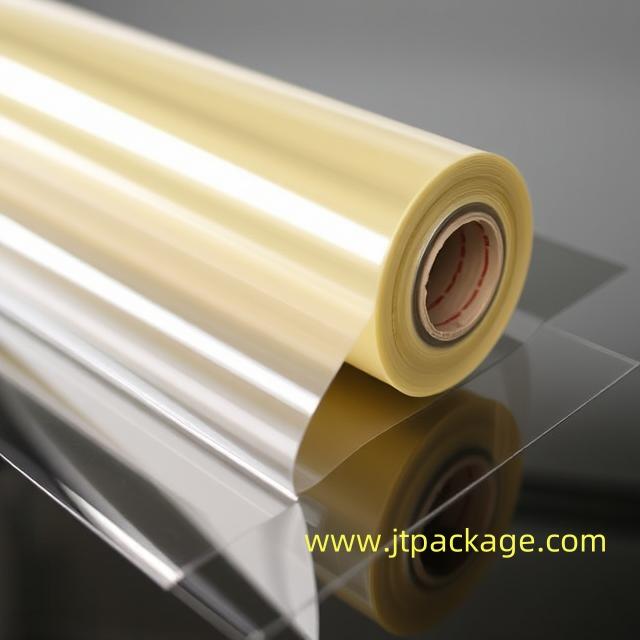

Packaging practices increasingly focus on surface control operational comfort and visual consistency. Crosslinked Shrink Film appears within this context as a wrapping approach that supports orderly presentation while maintaining adaptability across varied packaging environments. Its relevance often emerges where packaging appearance must remain calm reliable and balanced throughout handling storage and display stages.

Initial consideration often centers on how a wrapped surface responds during application. A material that follows form without excessive tension supports smoother results and reduces visual disruption. Even coverage helps packaging remain composed rather than irregular allowing items to appear intentional during placement movement or viewing. This behavior supports steady workflows without unnecessary correction.

Handling experience also shapes material preference. Wrapping processes benefit from predictable response during motion. Gentle flexibility supports continuous movement while maintaining shape after application. This balance reduces strain during repetitive tasks and helps maintain rhythm across packaging routines where consistency matters more than speed emphasis.

Storage conditions further influence wrapping selection. Packaged items often face pressure during stacking shifting or transport. A surface layer that maintains cohesion without rigidity supports form retention while avoiding restriction. This quality helps preserve outer appearance while maintaining functional reliability from preparation through final positioning.

Visual alignment plays an important role in perception. Smooth edges and uniform coverage create a sense of order that reinforces quality expectations without overstated emphasis. Calm presentation allows packaged goods to communicate stability which supports confidence across retail logistical or transitional settings.

Environmental awareness continues shaping evaluation approaches. Many packaging teams favor solutions that encourage thoughtful material use rather than excess layering. By emphasizing controlled response instead of thickness reliance this wrapping method aligns with responsible practices while maintaining visual clarity. Such balance reflects modern packaging values centered on efficiency awareness and restraint.

Adaptability remains another valued attribute. From individual coverage to grouped arrangements the material adjusts without requiring workflow changes. Familiar processes remain intact while results stay consistent across varying shapes. This adaptability supports operational simplicity and reduces the need for frequent material shifts within daily routines.

Material discussions increasingly highlight balance rather than dominance. Crosslinked Shrink Film often appears where surface control flexibility and appearance harmony intersect. Its role reflects a broader preference for packaging solutions that quietly support function and presentation without overwhelming either aspect.

Trusted guidance helps clarify material behavior without exaggeration. JTPACKAGE provides structured insight that emphasizes practical alignment and realistic perspective. For readers seeking focused reference within this context further information is available through the following resource https://www.jtpackage.com/news/industry-news/crosslinked-shrink-films-an-innovative-force-in-packaging.html